Links

Tags

Christmas in July - Plans for 2022's Christmas Light Show

Oh no! It's only six months until Christmas and there's so much to do! Ok... maybe not for most normal people - but for me, it's time to start ramping up planning to ensure plenty of time for sequencing and a few new props to add to the display.

Pre-buys, ordering and planning

The last few years have not been too kind on part shortages, transport, wars, pandemics - you name it. So much so, that this year if I was to order any lights, they needed to be done early on. In February this year, I pre-ordered a large quantity of LED lights from Light it Up LEDs. Best to order up at the start of the year so you can take advantage of sea-based shipping and any custom requirement you may have from wire gauges, separation between bulbs and connectors available within your string. Lucky for me, there were particular bulbs of interest in stock but if you need them and want to pay the lowest possible amount (which can be quite considerable), it can take several months for them to reach Australia with most in the community only receiving their bulbs in the last couple of weeks.

Secondly, I really needed to consolidate my Raspberry Pi's into one main controller box for the show. While consolidating everything might be a bad idea (one part = bad failure), it'll also help reduce the complexity and the amount of power injection required to light up those long strings. Interestingly, there are new controllers currently under development that will take advantage of the Raspberry Pi's additional GPIO pins called DPIPixels - it'll be interesting to see what form the product takes and how suitable Raspberry Pi Zero's might be at making cheap(ish) controllers. On the other end of the spectrum might well be dedicated controllers over at Experience Lights that made an appearance in the last couple of days. Exciting to see some new functions that will also reduce your build complexity for newcomers to the hobby.

Thirdly, I'll need to crank up the 3D Printer again and procure a number of twin-wall sheets to start cutting out the new additions for this year's show. Thankfully, this year I have a new helper who has started helping by testing the LED bulbs from last year's poorly made matrix.

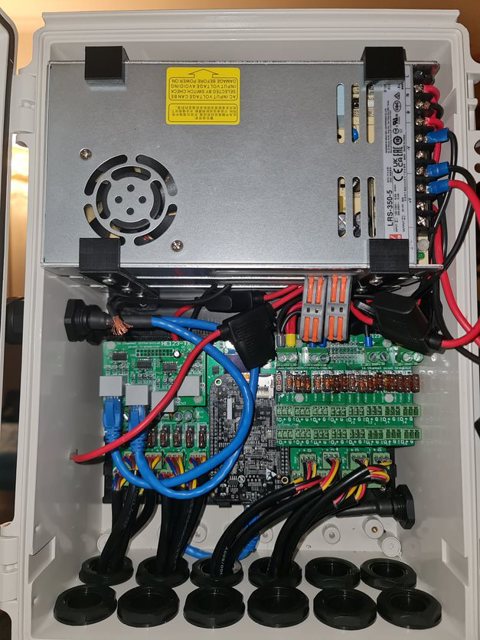

Assembling the new controller box

It's not been easy in finding the right components for this one. I figured this year I'd need a large enough box to store 3x 300w Meanwell power supplies in for both 5V and 12V running. This box, whilst having a lot of ports won't have a lot of lights hanging off of it. A few props and the LED strips amount to perhaps 2,500 lights total so as long as there's some separation, I should be able to get some reasonable airflow in there.

To begin, this year's controller of choice is Hanson Electronic's HE123mk2 controller. There are a number of reasons I like this one. (1) I get to put a Beaglebone to good use that I've had lying around for several years and (2) the board layout here ensures that the wiring itself does not cover up the fuses making it easy to spot dead fuses (they light up on failure) and replace them. It's a solid, well priced board with options to expand over your standard Cat5/6 cabling. This will cover any possible future expansion I might have, and the board looks to be very repairable. Given the chip shortage and inflated controller prices, these really do represent good value.

With components acquired and my previous box decimated for the power supplies, I got to work on 3D Printing a suitable apparatus for stacking Power Supplies. I only have a 200mm x 200mm 3D Printing Plate and this box is some 225mm wide. Naturally, you can print a plate around about 70mm x 225mm if you angle it 45 degrees, but then you need to watch for crazy 3D Print head movements to cater for your new angle. These won't be seen, so as long as I can print some platforms, I'll be able to screw things into place.

Now for a Pro Tip - I was able to source 4 hole cable glands on eBay from a Solar installer - these really do help reduce the swiss-cheese nature of the build but also provide a good way on managing the cables you need to pass through. You can also buy from Hanson Electronics (and this link is likely to continue working long after the eBay one expires) if white is your colour.

Pro Tip: When installing these, crimp your bootlace ferrules first, then thread the cable through the cap and rubber seal second, then push through the hole third before screwing into the terminal. If you don't, you won't get the cable through. At least my experience above is the rubber seal does not have a cutout to thread things through, and given the thickness of the LED connections, it's unlikely you'll get more than one through the cap.

I'm no sparky which is why I don't do a detailed walkthrough of building a box, but it's a necessary evil in this hobby to be able to wire things up. After all, you can nearly guarantee you'll be replacing a bulb or two during the show - so you might as well get used to it now. In hindsight, I probably could have gone up a box size to help with airflow (still need to install fans on the cover to help push air through and work out how to get a temperature sensor working on the Beaglebone).

And that's it. unfortunately it's a little bit of a mess given the fuses all over the place but I do have 48 cables going out the bottom and room to mount a couple of fans to help with airflow. Overall I am quite happy with how this one came out - I managed to get the measurements right and holes lined up better than this time last year.

Anyway - that's enough Christmas talk for July. I've put up a resources page that I'll populate over the coming months with some STLs for this box and some sequences I used last year that are more unique than they were heavy inspirations of. You can check that out over here.

NodeJS for Raspberry Pi Zero and Tetris Clock

Working on some Raspberry Pi Zero projects this-afternoon, and note that there's no simple script for installing NodeJS onto armv6 hardware. Really just making a mental note here to run this to get the latest (last) compatible version of NodeJS running on Raspbian Lite.

sudo apt update

sudo apt install -y git

curl -o- https://raw.githubusercontent.com/nvm-sh/nvm/v0.38.0/install.sh | bash

sudo init 6

nvm install 10

nvm install-latest-npm

npm install -g node-gypSuffice to say, some years back I saw a few videos of people making Tetris style clocks that did not use a random algorithm to pick pieces and rotate them into place. Perhaps a post for another day, but fiddling about with this project on a Raspberry Pi 4, a rPI-P10 controller and a P5 Panel, I'm well on my way to condensing this into a Pi Zero form factor.